Precision Redefined: Elevate Your Products with Advanced CNC Milling Services

In the rapidly evolving landscape of manufacturing, precision is the key to creating products that meet the highest standards of quality and functionality. Advanced technologies have played a pivotal role in reshaping traditional manufacturing processes, and one such innovation that stands out is Computer Numerical Control (CNC) milling. This article explores how CNC milling services are redefining precision in manufacturing and how they can elevate the quality of your products.

Understanding CNC Milling

CNC milling is a cutting-edge manufacturing CNC milling service that utilizes computer-controlled machines to shape and cut various materials with unparalleled accuracy. Unlike traditional milling methods, which rely heavily on manual operation, CNC milling automates the entire process, ensuring consistency and precision in every detail. The heart of CNC milling lies in the programmed instructions that guide the machine through complex cutting, drilling, and shaping tasks.

Unmatched Precision through Automation

The automation aspect of CNC milling is a game-changer for manufacturers aiming to achieve precise and repeatable results. The computer-guided machines follow predefined instructions with incredible accuracy, reducing the margin of error to almost zero. This level of precision is particularly crucial in industries where tight tolerances and intricate designs are non-negotiable.

Advantages of CNC Milling Services

- Consistency Across Production Runs

CNC milling ensures that each piece produced is an exact replica of the one before it. This consistency is vital for industries such as aerospace, automotive, and medical, where uniformity is a prerequisite. Manufacturers can confidently rely on CNC milling to deliver batches of products that meet the same high standards without variation.

- Complex Geometries Made Simple

One of the standout features of CNC milling is its ability to handle complex shapes and intricate geometries with ease. Traditional machining methods may struggle with the intricacies of modern product designs, but CNC milling machines can effortlessly execute intricate cuts and contours, allowing for the production of highly sophisticated components.

- Enhanced Efficiency and Faster Turnaround

CNC milling significantly reduces production time compared to traditional methods. The automated nature of the process, coupled with the ability to program multiple tasks into a single machining operation, streamlines the manufacturing workflow. This efficiency not only accelerates production but also contributes to cost savings.

Applications Across Industries

The versatility of CNC milling makes it applicable to a wide range of industries, each benefiting from the precision and efficiency it brings to the table.

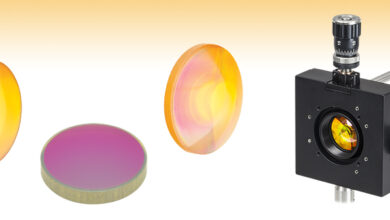

- Aerospace Engineering

In the aerospace industry, where components must meet stringent standards for safety and performance, CNC milling ensures the production of intricate parts with the required precision. From engine components to structural elements, CNC milling plays a pivotal role in creating reliable and high-performance aerospace products.

- Automotive Manufacturing

Automotive manufacturers leverage CNC milling to produce precision-engineered parts that contribute to the safety and performance of vehicles. From engine components to intricate interior elements, CNC milling enhances the overall quality and reliability of automotive products.

- Medical Device Production

The medical industry demands the highest level of precision in manufacturing, and CNC milling delivers on that requirement. From surgical instruments to implant components, CNC milling ensures the production of medical devices that meet strict quality and accuracy standards.

Choosing the Right CNC Milling Service Provider

To fully capitalize on the benefits of CNC milling, choosing the right service provider is crucial. Consider the following factors when selecting a CNC milling partner:

- Experience and Expertise

Look for a service provider with a proven track record in CNC milling. Experience and expertise in handling diverse materials and complex projects are indicative of a reliable and skilled partner.

- State-of-the-Art Equipment

Ensure that the CNC milling service provider employs the latest and most advanced milling machines. State-of-the-art equipment contributes to higher precision and efficiency in the manufacturing process.

- Quality Control Measures

A reputable CNC milling service provider will have stringent quality control measures in place. This includes thorough inspections and testing to guarantee that each product meets the specified standards.

Conclusion

Precision redefined through advanced CNC milling services is not just a manufacturing evolution; it’s a revolution. The ability to produce intricate components with unmatched accuracy has far-reaching implications for industries that demand excellence. Whether you are in aerospace, automotive, medical, or any other precision-critical industry, embracing CNC milling services can elevate your products to new heights of quality and reliability. As technology continues to advance, the future of manufacturing undoubtedly revolves around the precision redefined by CNC milling.