Exploring Pigging Paint: Applications and Benefits in Pipeline Operations

Pigging paint, also known as pipeline pigging paint, plays a crucial role in pipeline maintenance and operational efficiency across various industries. This article delves into the uses, benefits, and applications of pigging paint, highlighting its importance in ensuring pipeline integrity and optimizing pigging operations.

Introduction to Pigging Paint

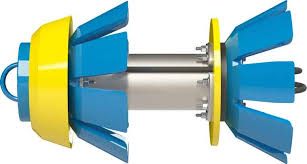

Pigging paint refers to specialized coatings or paints used in conjunction with pipeline pigging operations. These coatings serve multiple purposes, including enhancing pipeline visibility, protecting against corrosion, facilitating efficient pigging operations, and ensuring compliance with industry standards and regulations.

Applications of Pigging Paint

- Enhanced Pipeline Visibility:

- Pigging paints are often brightly colored to enhance visibility and facilitate tracking of pigs (devices used in pigging operations) within the pipeline.

- Colors such as red, yellow, or orange are commonly used to differentiate pigging tools from pipeline surfaces, aiding in visual inspection and monitoring during pigging operations.

- Corrosion Protection:

- Pigging paint formulations include corrosion-resistant properties, helping to protect pipeline surfaces from environmental factors, chemical exposure, and wear over time.

- These coatings act as a barrier against moisture and contaminants, extending the lifespan of pipelines and reducing maintenance costs.

- Facilitation of Pigging Operations:

- Smooth and consistent application of pigging paint reduces friction and resistance encountered by pigs as they travel through pipelines.

- This improves the efficiency of pigging operations, minimizes energy consumption, and enhances the overall integrity of product flow within the pipeline.

- Regulatory Compliance:

- Pigging paints are formulated to meet regulatory requirements and industry standards for pipeline maintenance and safety.

- Compliance with coating specifications ensures that pipelines remain operational, environmentally sound, and in adherence to regulatory guidelines.

Benefits of Using Pigging Paint

- Operational Efficiency:Enhanced visibility and reduced friction contribute to smoother pigging operations, minimizing downtime and optimizing pipeline throughput.

- Cost Savings:Protection against corrosion and wear extends the lifespan of pipelines, reducing maintenance and replacement costs over time.

- Environmental Protection:Corrosion-resistant pigging paints help prevent leaks and spills, minimizing environmental impact and ensuring regulatory compliance.

- Safety:Improved visibility aids in the safe and efficient retrieval of pigs during maintenance and inspection activities, enhancing overall operational safety.

Considerations for Choosing Pigging Paint

- Pipeline Material and Condition:Selection of pigging paint depends on pipeline material (e.g., steel, concrete) and condition (e.g., internal pressure, temperature).

- Environmental Factors:Consideration of environmental conditions such as temperature variations, chemical exposure, and UV radiation affecting paint performance.

- Application Method:Proper surface preparation and application techniques ensure effective adhesion and performance of pigging paint coatings.

Conclusion

pigging paint plays a vital role in pipeline maintenance and operational efficiency by enhancing visibility, protecting against corrosion, and facilitating efficient pigging operations. Industries such as oil and gas, food and beverage, pharmaceuticals, and chemicals benefit from the application of pigging paints to ensure pipeline integrity, regulatory compliance, and cost-effective maintenance practices. By choosing the right pigging paint and adhering to best practices in application and maintenance, organizations can optimize pipeline performance and achieve long-term operational reliability.